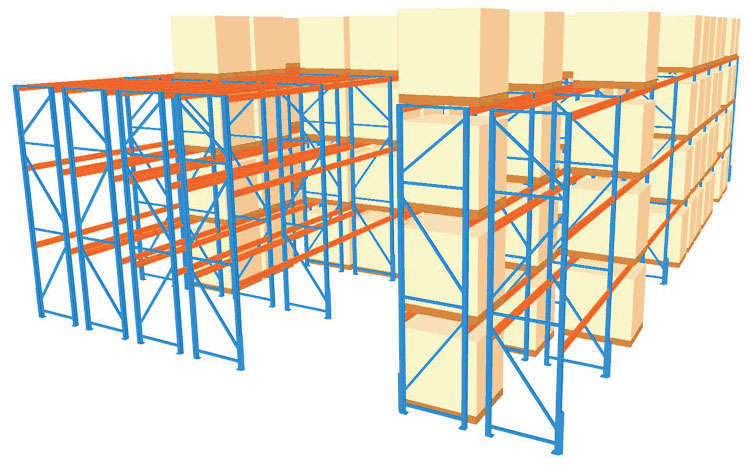

DOUBLE DEEP

This is also a type of selective racking (Selective Rack), which is made up of 2 rows of double shelves facing each other so that the usable warehouse floor area increases by reducing the space of the aisles.

With nearly 30 years of experience, HAI MY has launched the Double Deep racking solution to accommodate 2 pallets in depth to provide to many customers. This solution has brought maximum efficiency to the Selective Rack warehouse.

Attributes

DOUBLE DEEP

- Pallets are stored two deep and are accessed using special trucks with pantograph of telescopic forks.

- The cargo capacity in the warehouse is higher than that of the Selective racking.

- The base investment per Double Deep Racking is estimated to be the same as the base investment for the Selective Racking.

- Require a forklift with a fork that controls deep inwards to bring pallets into and out of racks.

- Load weights and height limited to forklift capacity.

- Operator must remove front pallet in order to access rear.

- Last In First Out (LIFO) inventory is easily accommodated by placing the last pallet in the front slot so it is the first to be picked.

- Because the warehouse racks are arranged one after the other, the picking space is reduced.

- Floor Area Utilization: 50% (High)

__ Double Deep Rack Illustration __

DOUBLE DEEP RACK STORES PALLETS DEEPLY INTO THE RACKING SYSTEM, HELPS INCREASING GOODS STORAGE CAPACITY

__ Images of Double Deep Industrial Racking System deployed by HAI MY Company __